IN THE EVENT OF AN EMERGENCY THIS SITE IS NOT MONITORED. FOR CURRENT INFORMATION GO TO HTTPS://EMERGENCY.MARINCOUNTY.GOV.

Fire-Resistant Siding

Siding Materials & Coatings

Siding products can be classified into three basic categories:

- non-combustible

- ignition-resistant

- combustible

The California Building Code defines the terms based on a material’s ability to pass a standard test.

This is an example of a noncombustible siding of fiber-cement shingles, designed to look extremely realistic–almost indistinguishable from highly combustible cedar shake shingles. This product is available with permanent, pre-impregnated colors or primed and paintable, is durable, rot-resistant, and can be significantly less expensive than wood shingles when considering the complete cost of installation, painting, and maintenance. Photo credit: James Hardie

Non-Combustible

Common non-combustible materials include three-coat stucco, metal siding, and fiber cement siding.

Ignition-Resistant

An ignition-resistant material should not be confused with ignition-resistant construction. The latter takes into consideration all components and materials on the outside of the house, as well as the vegetation management plan used in the defensible space zone around the home. Wood that has been treated with an exterior fire-retardant chemical, and that has passed a standard flame spread test after undergoing a specified weathering procedure consisting of wetting and drying cycles, is called ignition resistant. In California, combustible materials can be used in ignition-resistant construction.

Combustible

The most common combustible siding products include solid wood and other composite wood products (plywood, oriented strand board, and other compressed wood fiber products) and siding made from vinyl or other plastics.

Wood Particle/Shingle Siding & Trim

Testing at the University of California Fire Research Laboratory has shown that, when ignited, compressed wood particle or fiber siding products and wood shingle siding will result in more rapid vertical flame spread up the wall, and more rapid penetration through the lap joints and into the stud cavity. Similar results have been observed with vinyl siding. In both of these cases, underlying wood or gypsum sheathing would improve the resistance to flame penetration at a lap joint.

Combustible trim is also vulnerable to ember attack and potential flame contact exposure, particularly at internal corners. In these locations the trim can either be applied on top of siding that extends all the way to the corner or adja- cent to siding when trim is applied directly to the studs. When applied directly to studs, the trim-to- siding gaps should be protected and maintained.

These caulked joints are likely to fail if subjected to flames. Vegetation is commonly planted in these corners, which are also susceptible to accumu- lating windblown vegetative debris. During wildfires, this area would also be susceptible to the accumulation of windblown embers. Once ignited, the proximity of adjacent trim pieces makes it easier for flames to propagate vertically up the wall. Therefore, internal corners would be a good location for a noncombustible or ignition-resistant material.

Siding Patterns & Assembly

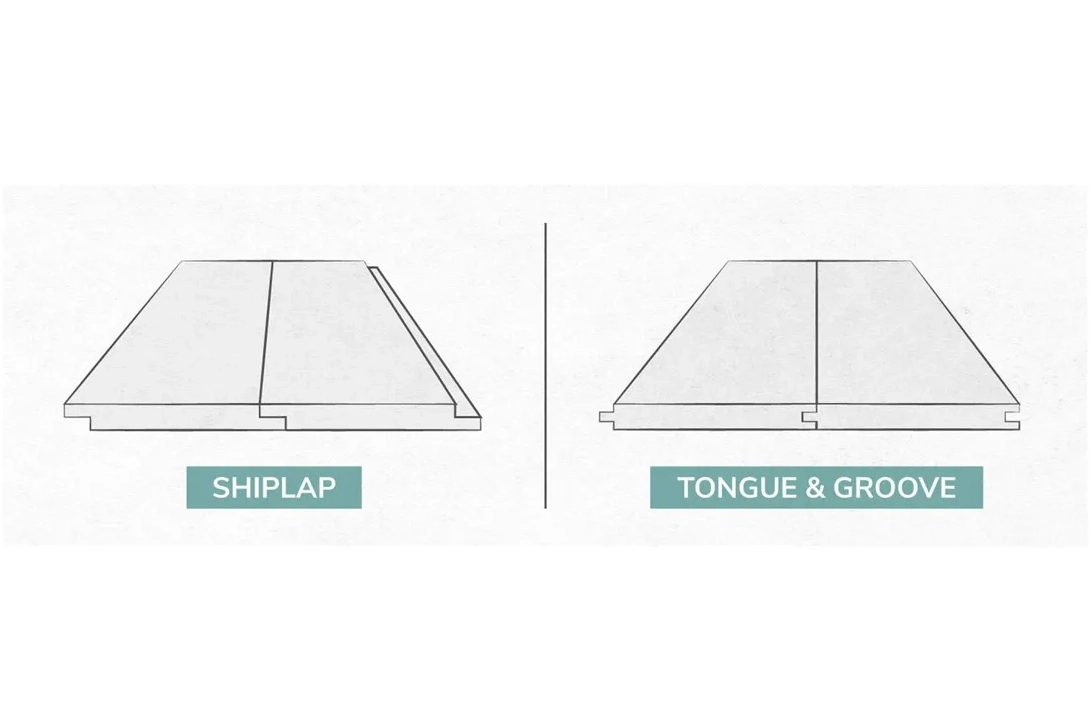

Testing of siding products conducted at the UC Fire Research Laboratory showed that the siding joint is the most vulnerable part of a combustible siding assembly. Flame penetration through the siding occurred more readily at less complicated lap joints. For example, a ship lap or tongue-and-groove lap joint provided greater protection against flame penetration into the stud cavity compared with a plain bevel joint.

With sustained flame exposure, even noncombustible siding materials will eventually fail. For example, failure occurred in a noncombustible lap siding product after approximately 22 minutes of a flame contact exposure. Failure in these materials occurred either as a result of increased heat transfer through the material, with subsequent ignition of a stud, or flame penetration at cracks that developed. Use of structural sheathing, located underneath the siding, provides enhanced protection against flame penetration at lap joints. Because of seismic (earthquake) design issues, sheathing is commonly used, particularly in California.

Prolonged exposure from the wildfire itself is unlikely, since the duration of the main flaming front at a given building is relatively short (5 to 10 minutes at the most), and even combustible siding products can protect against penetration for these time periods. Prolonged radiant or flame contact exposure from abundant near-home vegetation, or other buildings in proximity, could more easily result in joint penetration.

In summary, although siding is an important component in terms of providing protection for the building from the weather, and also in terms of the aesthetics of the building, in most cases it is less important from a wildfire exposure perspective compared with other components and assemblies. With proper selection and maintenance of near-home vegetation, most siding products will be able to resist typical wildfire exposures. However, viewing the side of the building as a system, use of noncombustible or ignition-resistant materials will reduce the potential fire exposure on windows and the eave area of a building.

Fire-Retardant Treatments & Coatings

Exterior rated, fire-retardant-treated (FRT) wood products are pressure-impregnated with chemicals that improve the fire performance characteristics. These wood products undergo a processing step whereby these chemicals are fixed or otherwise contained to prevent or minimize leaching of the chemical. The process is similar to that used in preservative-treated lumber, which contains chemicals to resist attack from fungi and other wood-destroying organisms. In order to qualify as an exterior-use product, the treated wood must undergo accelerated or natural weathering cycles and pass subsequent fire tests to provide evidence of a prescribed level of performance over the intended service life of the product. There are practical and scientific reasons why a natural weathering cycle equivalent to the intended service life is not required prior to the product being accepted for use.

Instead of leaching losses from wetting, the more likely reduction in performance will be from in-service weathering (i.e., weathering resulting in the loss of wood fibers from the surface, thereby depleting the fire-retardant chemicals). Weathering will be variable, depending on exposure (i.e., the north, east, south, and west sides of your home), but it has been shown to be a slow process. The weathering process can be reduced considerably with a periodic application of a penetrating stain or a film-forming coating.

Stains and coatings are used for aesthetic reasons, and also to improve the resistance to certain exposures (e.g., weathering, fungi, and insects). Film-forming intumescent paints and penetrating stains, applied in the field, have not been shown to provide long-term, improved protection from fire exposures. None of these products have demonstrated long-term, fire-resistance performance in an exterior environment. Until these products can show adequate performance after a defined weathering procedure, they should not be relied on to improve the fire performance of exterior-use building materials.

A gel coating is a new fire protection alternative that is becoming more available to the homeowner. Gel coatings can be effective, assuming they are applied correctly and address points of fire entry as discussed in this publication. Gel coatings are purchased in a concentrated form and can be applied to the home using a garden hose and an attachment that is supplied by the gel supplier. These coatings lose effectiveness with time (in the order of hours) as a result of water evaporation, but there is no data that evaluates the rate at which this reduction in effectiveness occurs. We do not think it is warranted to rely on a coating in lieu of managing vegetation or improving building materials or design.