IN THE EVENT OF AN EMERGENCY THIS SITE IS NOT MONITORED. FOR CURRENT INFORMATION GO TO HTTPS://EMERGENCY.MARINCOUNTY.ORG.

Fire-Resistant Vents

Wildfires pose a significant threat to ecosystems, communities, and infrastructure. One often overlooked aspect of this threat is the vulnerability of vents to wildfire. Vents allow outside air to circulate under the floor or in the attic to prevent the moisture buildup that encourages mildew and rot. While designed to expel air and maintain a balance of pressure, they can inadvertently become entry points for embers and burning debris during a wildfire. Embers carried by the wind can enter vents and ignite materials inside, leading to the rapid spread of fire within a structure. This IBHS video shows that embers can easily enter homes through vents that are not properly screened.

Fire Safe Marin Recommends:

- Use manufactured and California-approved vents (see below) to retrofit existing attic, soffit, basement, foundation, and gable vents, where possible.

- Alternatively, Cover all existing vent openings with 1/8-inch or 1/16-inch wire mesh.

- Common 1/4″ screens are ineffective, and should be replaced or retrofitted*.

- Do not use fiberglass or plastic mesh because they can melt and burn.

- Protect vents in eaves or cornices with baffles to block embers, backed by 1/16″ wire mesh (mesh alone is not enough).

California-Approved Vents

The importance of ember and flame entry into vents during wildfires has resulted in the development of commercially available vents designed to resist the intrusion of embers and flame, and recommendations for new or retrofit vents to protect existing openings. Ember-resistant vents are addressed in Chapter 7A of the California Building Code. Chapter 7A requires that vents be able to resist the intrusion of embers and flames and shall be protected by corrosion-resistant and noncombustible wire mesh screen with 1/16 to 1/8-inch openings.

Airflow Considerations

In addition to information regarding ember and flame intrusion resistance, you should also be looking at available airflow information. This is normally given in percent net free area and provides information on how much area the wire (or other device(s) used in the vent design) is occupying. For comparison purposes, 1/4 – inch mesh screen has a net free area of 81%. One-eighth inch and 1/16 – inch mesh screens have net free areas of 75% and 71%, respectively. Screening with smaller openings typically uses smaller diameter wire.

*Consult with a building contractor, architect, or engineer to ensure that adequate ventilation exists when installing ember-resistant vents which may restrict airflow.

Approved Vent Manufacturers

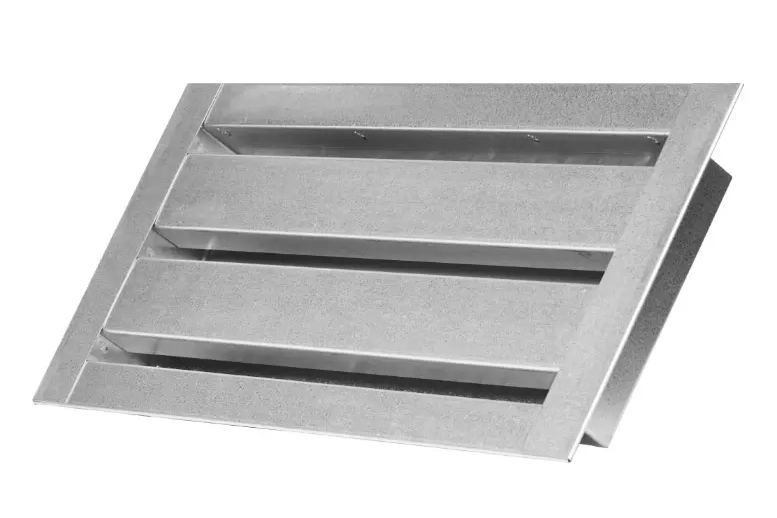

Several vents have been accepted for use by the Office of the State Fire Marshal – these vents can be used in applications where ember and flame intrusion resistance is required. These vents typically use a combination of screening and other design features such as baffles or intumescent materials to resist the intrusion of embers and flames.

Vents & Ember Research

Read the report “Vulnerability of Vents to Wind-Blown Embers” to learn about recent research conducted to evaluate vents for wildfire ember resistance. This report adds to a growing body of literature on how buildings can ignite by wind-blown embers, by focusing on the vulnerability of vents to embers.

Summary of Findings

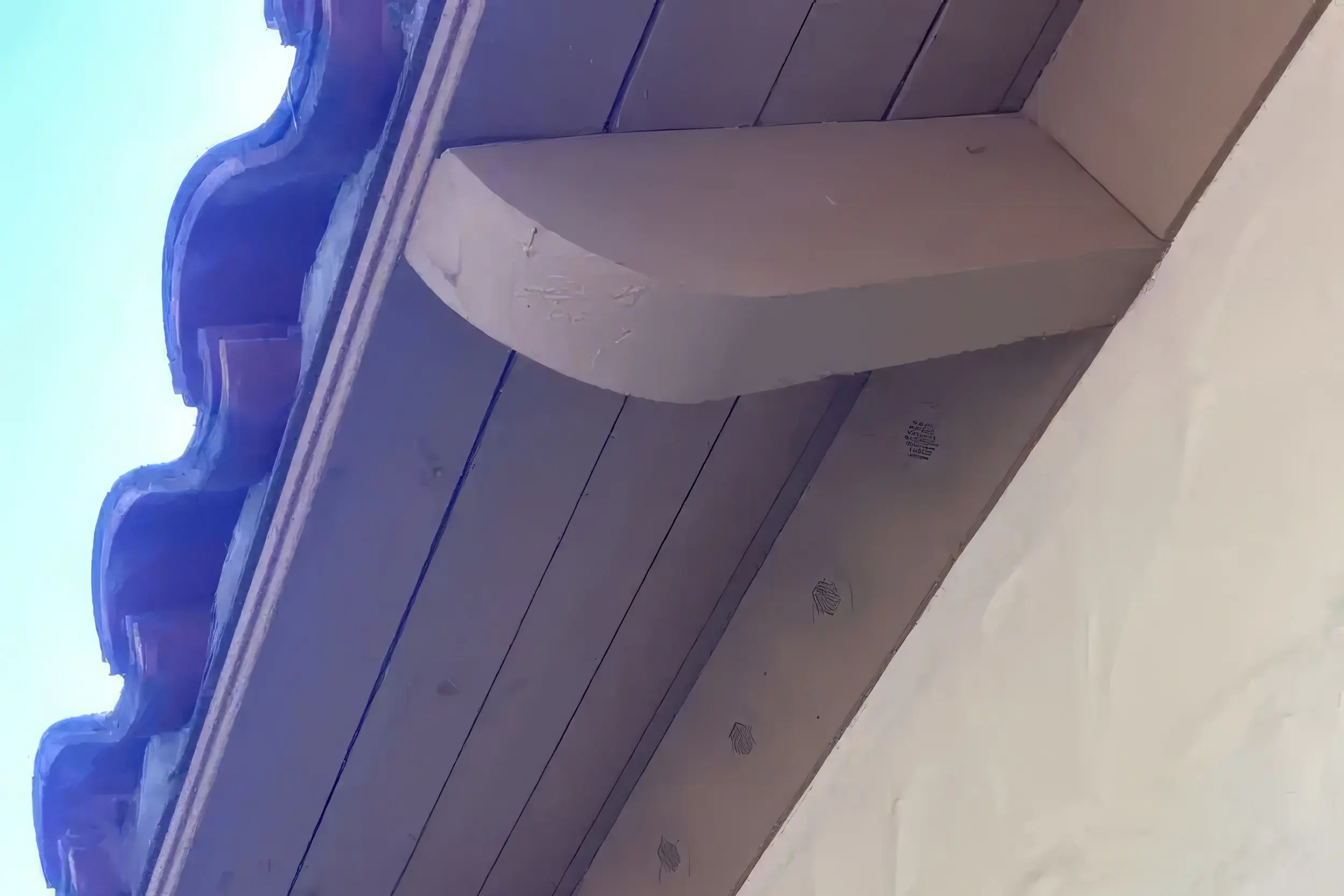

- There are two options for inlet vents, both located in the under-eave area: vents in the between-rafter blocking in open-eave construction, and, vents in the soffit material in soffited-eave construction. Vents located in soffited-eave construction were shown to limit ember entry and should, therefore, be the preferred construction type.

- One-quarter inch (6 mm) mesh screening should not be used to cover any vent. Finer mesh sizes of 1/8 – inch (3 mm) or 1/16 – inch (1.5 mm) are preferred. The finer 1/16 – inch mesh screen requires more cleaning-related maintenance to remove the debris that can accumulate on the screen surface.

- The wildfire-resistant vents used in the gable end location performed better than the respective backing screen mesh alone.

- Due to the relatively large size and vertical orientation of gable end vents, they should be avoided. If alternatives are not possible, a wildfire-resistant gable vent that has passed ASTM E2886 should be used.

- Avoid using non-wildfire-resistant off-ridge and ridge vents. However, of the ridge and off-ridge outlet vent options, the following performed well:

- Miami-Dade wind-driven-rain-compliant ridge vent

- Wildfire-resistant off-ridge vent

- Turbine (off-ridge) vent

- Wind-blown vegetative debris must be removed from the inlet of all ridge and off-ridge vents, paying particular attention to vents with plastic components. Plastic components are commonly used in ridge vents.

FAQS

When I went to purchase a Vulcan vent (or Brand Guard vent, Embers Out vent, etc.) I was told that contractors are not recommending this product or others like it because it does not really allow for airflow and that it is not correctly engineered. I was told this by the person selling the product; is that correct?

This is incorrect – a half-truth at best. Some modern houses are engineered to require a precise amount of ventilation. Most homes in Marin are much older, and their vent openings were not calculated so precisely (if at all). If you have a brand new home that had the ventilation calculated exactly to the square inch, then it’s true, these vents might reduce airflow and require a small number of additional vents to be installed to bring the airflow back up to where it was. Keep in mind that many of these newer homes ALREADY HAVE EMBER RESISTANT VENTS, since these vents have been in common use since 2008 on new construction.

So, yes, these vents may move slightly less air than older vents. Many homes have more than adequate airflow, so it’s not going to cause problems. If there were inadequate airflow, it’s usually quite easy to add additional vents to make up for the reduced flow through ember-resistant vents. We strongly recommend that these vents be installed on all homes in Marin’s WUI and adjacent areas – they are approved by the State Fire Marshal, and any contractor that recommends otherwise is likely just unfamiliar with them or unwilling to do the extra work to add new ventilation.

I am considering backing up my ⅛ – inch vent screens with 1/16 – inch screen. However, I am concerned about the resulting decrease in airflow.

Are you considering additional screening for attic and crawl space areas? Particularly in the more temperate climates where we live, attic spaces are typically warm spaces and therefore dry spaces, so some decrease where airflow is otherwise currently adequate shouldn’t be a problem. Moisture-related degradation problems could develop should a roof leak occur, but if that were to happen, even ventilation to code may not be sufficient. With crawl spaces, it would depend on soil moisture conditions, but there are other mitigation strategies that could be used in crawl spaces that could dramatically reduce the amount of required venting. For both attics and crawl spaces adding vents is always an option, although usually not a very satisfying one. You will note that in the IBHS NFPA one-page document here:

Is the cost of these ember and flame-resistant vents worth the money?

One-eighth inch mesh screening is much less expensive than any of the California-approved fire and ember-resistant vents. The question is how likely is it that a particular vent location will experience a flame impingement exposure. If that location is likely to see flames, then the cost of the flame and ember-resistant vent would likely be considered a good investment, even at $40 per vent. But, if the vent is only likely to see embers, mesh alone would be adequate, assuming easy-to-ignite materials were not stored on the inside of the vented space and close to the vent (cardboard boxes stored in the attic, etc.). Screening minimizes the size and number of embers that can potentially pass through the vent, but it won’t stop them completely. Embers that pass through 1/8 – inch mesh screening have sufficient energy to ignite finer fuels, but they (the embers) need something on the interior side to allow enough of them to accumulate in one spot.

These are vents that could be expected to see flames:

- Through-roof vents (off-ridge or ridge) that have a propensity to collect needle and/or leaf debris at the inlet to the vent. Embers can ignite this debris, and flames impinging on the vent inlet could be expected.

- A gable end vent on an exterior wall with combustible siding material. If the siding ignites, flames could travel up the wall to the vent and under-eave area. This vertical/lateral flame spread to reach the vent can happen faster than the fire can burn through the siding and sheathing. You will have to judge how likely it will be that the siding will ignite. Does the home have a good defensible space, including near-home zones (horizontal and vertical)? If “yes”, then maybe embers are the only thing the vent will have to resist. Is a neighboring home within 35 (or so) feet? If “yes”, then that home may be the threat if it ignites.

- Vents in the blocking of open-eave construction (see explanation above).

- A crawl space vent, particularly if the near-home (zero) zone has a lot of combustible materials in it.

- Vents that present an opening that is perpendicular to wind-flow (e.g., a gable end vent, vents in the blocking of open eave construction, crawl space vents, “dormer” style off-ridge through roof vents) are vulnerable to the entry of embers. Vents that present an opening that is parallel to wind flow (for example, a vent in soffited-eave construction) are less vulnerable.